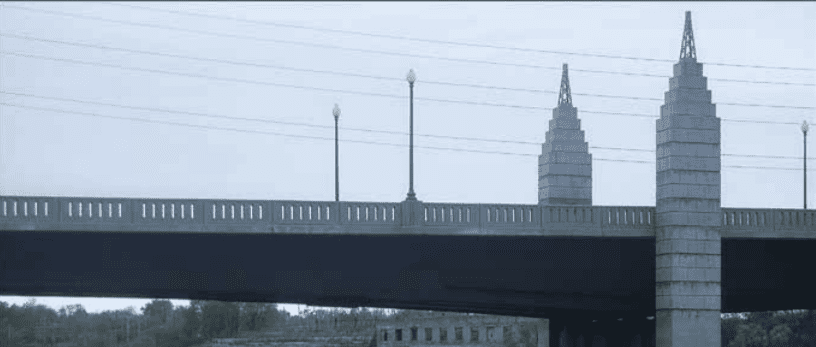

Owner: New York City Department of Transportation

Project Description

The Manhattan Bridge connects Lower Manhattan and Brooklyn, carrying vehicular traffic, transit trains, pedestrians and bicycles across the East River. This prominent suspension bridge has undergone numerous maintenance and rehabilitation projects since its opening in 1909.

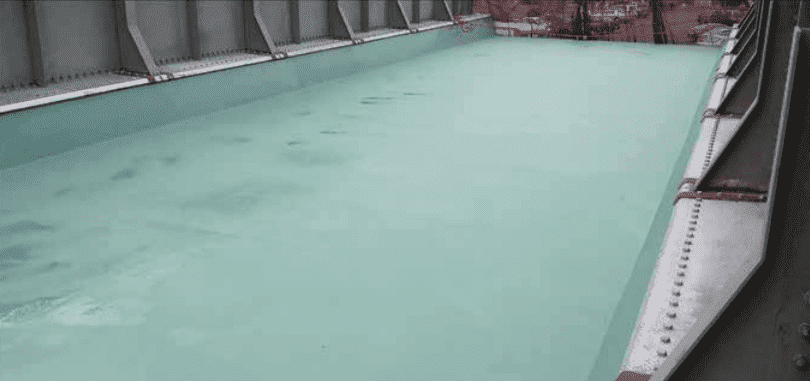

The latest reconstruction program included re-wrapping the main cables and replacing the suspender ropes. To ensure additional decades of continued use, D.S. Brown’s Cableguard Elastomeric Cable Wrap System was specified to protect the main cables against future corrosion.

Cableguard Elastomeric Cable Wrap System

Cableguard Elastomeric Cable Wrap System was specified for the Manhattan Bridge because it provides long-term protection for the bridge’s main suspension cables. This environmentally safe, longlife elastomeric wrap protects suspension and stayed bridge cables from corrosion and considerably reduces future maintenance costs.

The unique Cableguard protective wrap completely encapsulates existing surface coatings without scraping, grinding or painting before installation. The material also provides excellent UV and ozone resistance and is in use on installations worldwide.